Simple but powerful manufacturing

Composity enables you to better schedule row materials, inventory and labor cost and increase real-time visibility throughout the production cycle. Manufacturers can improve operations with master data management and automated data collection. You gain an accurate, complete product, material and inventory information.

Know and control your inventory

Extended capabilities for inventory control tracking, planning and costing of items. Composity gives you immediate visibility to accurate raw materials inventory in any warehouse, along with the ability to transfer or order materials quickly in response to production needs.

Works the way you want

Composity software adapts as your business evolves. You’ve got the flexibility to manage your production process exactly the way you want. Plan and control your manufacturing operations with customizable business processes. The system effectively supports all major business areas and accommodates to the needs of all your geographic locations.

Integrated with accounting

We know the next highest priority for business is managing their finances. With Composity you don’t need another second software to do this as our Accounting module is part of the overall components of Composity platform. Bring your financial information together with Composity Accounting module.

All the features you need

A perfect solution for any size organization.

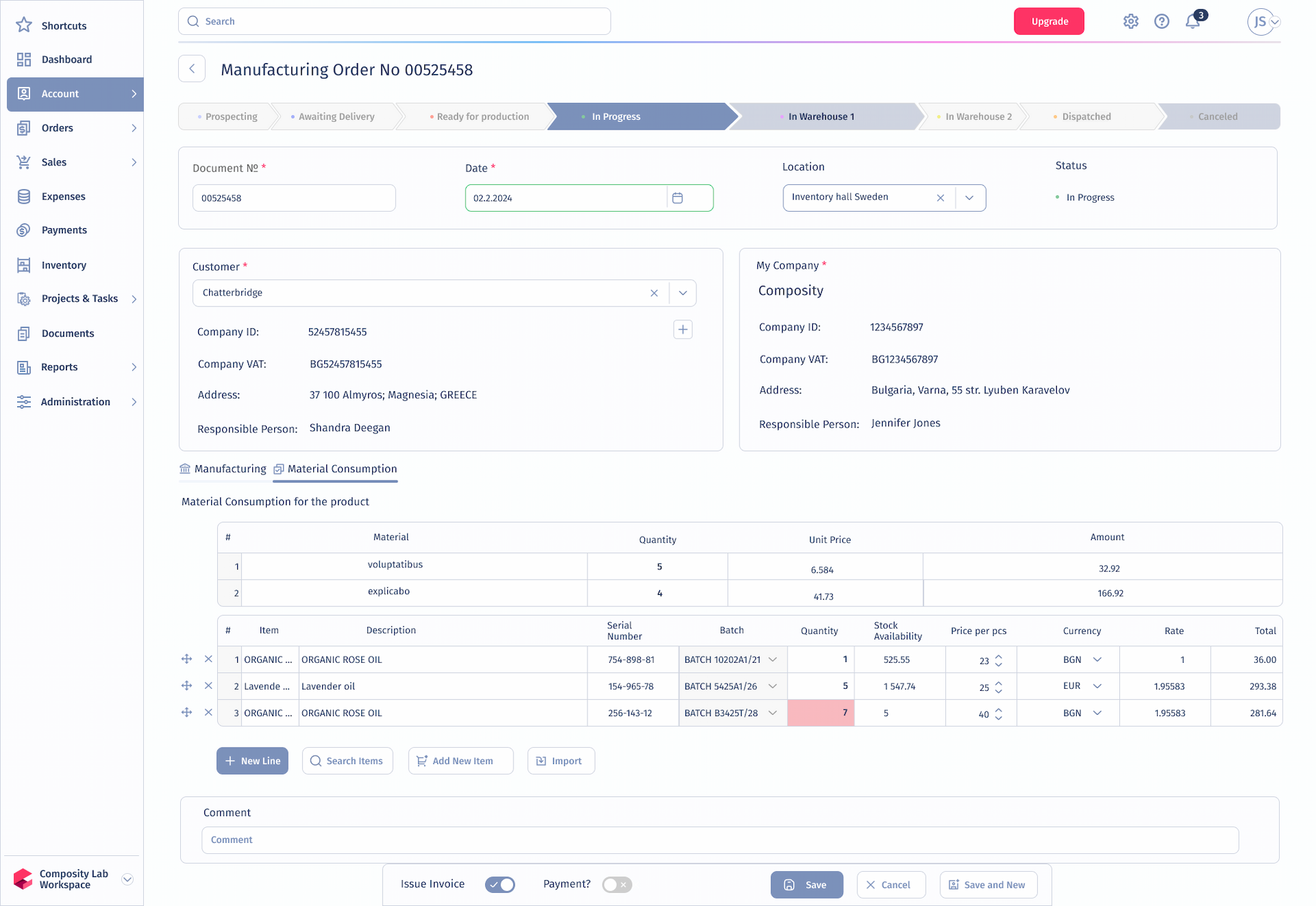

- MANUFACTURING ORDER

- MANUFACTURING STAGING

- BILL OF MATERIALS

- INVENTORY & WAREHOUSE

- REPORTS

Manage and monitor manufacturing operations.

Material consumption

To help you prepare production and procurement you need to calculate your materials needs. The system shows you the raw materials consumed per MO.

Available quantity indicator

When an item is added to a Manufacturing job the system will show you if this item is available and what is its current quantity.

Production stages

Add production stages to organize manufacturing jobs and track performance as manufacturing orders move through the shop.

Automate production receipt

New products are automatically received into your warehouse when an MO is finished.

Absorb labor and overhead costs

Enter time and costs for employees labor and other indirect costs.

Batches

Maintain full traceability throughout the lifecycle of the item.

Automatic inventory order

When the status of a manufacturing order is changed to ’’In progress’’ an automated inventory receipt is created. The system will ask you in which of your warehouses to stock the ready production.

Tasks

Create and schedule tasks to ensure they’re done in the proper order. Assign tasks to specific workers.